Products Description

The High-Precision Laboratory Asphalt Moisture Content Tester (TD612-A) is designed to accurately measure the water content in asphalt and bituminous materials. Using the Dean-Stark distillation method, it ensures reliable and repeatable results for laboratory quality control, research, and asphalt mixture production.

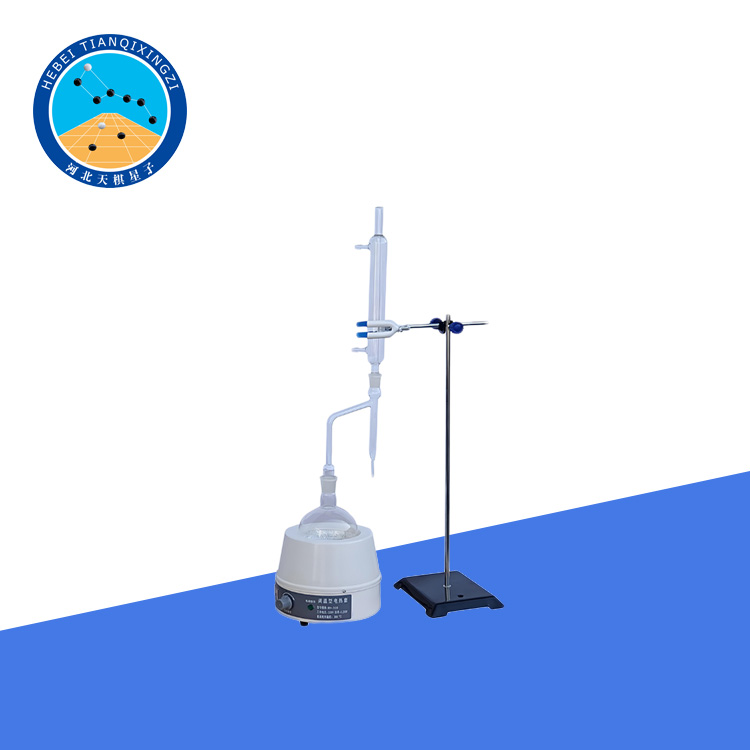

Asphalt Moisture Content Tester

Model:TD612-A

I. Product Introduction

The TD612-A Asphalt Moisture Content Tester Set is a high-precision laboratory apparatus designed for determining the moisture content in asphalt and bituminous materials. Manufactured according to JTG 3410-2025 (Highway Engineering Asphalt and Asphalt Mixture Test Specification), JT/T 1540-2025 (Low-Temperature Modified Asphalt), and GB/T 38075-2019 (Petroleum Asphalt for Rigid Pavement), and referencing ASTM D95 and ISO 3733, this tester ensures accurate and reliable results for quality control and research purposes.

II. Technical Parameters

part | Technical Specifications / Description |

Glass Beaker (Flask) | Hard glass, round bottom, short neck, Ø100mm, 500ml capacity; used for mixing sample with solvent |

Moisture Receiver | Precision graduated container with multiple scales: • 0–0.3ml: 10 divisions • 0.3–1ml: 7 divisions • 1–10ml: 0.2ml per division (Alternative receiver with similar precision may be used after verification) |

Condenser | Straight or bulb-shaped, inner tube Ø10mm, total length 350–400mm; outer jacket Ø40–50mm, length 250–300mm; end slanted; inlet/outlet near both ends; similar specifications allowed |

Iron Stand | Equipped with iron ring and clamp for securing flask and condenser |

Heater | Electric or gas stove recommended; stable temperature control to prevent local overheating |

Base Tray | Supports entire apparatus and ensures operational stability |

III. Operating Procedures:

1. Heat the flask and control the reflux rate of the condensate, ensuring that 2-5 drops of liquid drip from the slanted end of the condenser per second.

2. During reflux, stop heating when the water in the water receiver reaches the maximum volume mark. Wait until no more solvent drips out, then quickly remove the receiver and pour the solvent water into a graduated cylinder. Reassemble the cylinder and continue heating for reflux.

3. Near the end of reflux, if water droplets adhere to the inner wall of the condenser, briefly and vigorously boil the mixture in the flask to use the condensed solvent to wash as many water droplets as possible into the receiver.

4. When the volume of water collected in the receiver stops increasing and the upper layer of solvent becomes completely transparent, heating should be stopped.

5. After stopping heating, if water droplets remain on the inner wall of the condenser, pour solvent into the top of the condenser to flush the droplets into the receiver. If solvent flushing is ineffective, use the rubber end of a thin glass rod to scrape the water from the condenser into the receiver.

6. After the glass flask has cooled, disassemble the instrument and record the volume (Vm) of water in the receiver or graduated cylinder.

7. If the solvent in the receiver is cloudy and the water collected at the bottom of the tube does not exceed 0.2 mL, immerse the receiver in hot water for 20-30 minutes to clarify the solvent. Then cool the receiver to room temperature before recording the volume of water collected at the bottom of the tube.

IV. Main Advantages:

High-precision moisture determination

Complies with domestic and international standards

Durable glassware and sturdy support structure

Suitable for educational and industrial laboratories