Products Description

This equipment uses high temperature and compressed air in a pressure vessel to accelerate the aging of residues obtained from the rotating thin-film oven test method,the purpose is to simulate the oxidative aging of asphalt during road use,and to evaluate the antioxidant aging resistance of different asphalts under test temperature and pressure conditions.However, it cannot explain the influence of mixture factors or the impact of actual asphalt use conditions on aging.

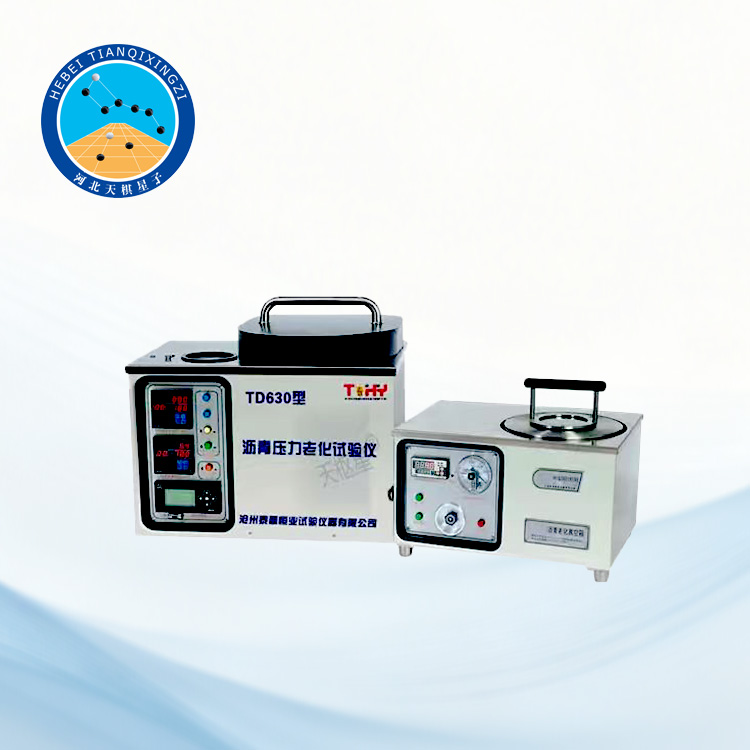

Asphalt Pressure Aging Vessel

Model:TD630-1

I. Product Introduction

This Asphalt Pressure Aging Vessel (PAV) is designed and manufactured by Hebei Tianqixingzi Inspection Equipment Co., Ltd. in accordance with the Chinese Ministry of Transport standard JTG D3410 (Specification for Testing of Asphalt and Asphalt Mixtures in Highway Engineering), and is referenced against international standards ASTM D6521, AASHTO R28, and EN 14769 for accelerated long-term aging of asphalt binders.

II. Instrument Configuration

1. One TD630-1 type asphalt pressure aging tester

Technical parameters:

Asphalt pressure aging system technical specifications:

① System power supply: 220V 50Hz

② Total input power: 2.5kW

③ Pressure control: Aging chamber 2.1±0.1MPa

④ Temperature control: Aging chamber 90-100±0.5℃

⑤ Time control: Aging chamber 20h±10min

⑥ Process Control: The system monitors and determines initial temperature, process temperature, outputs alarms and final pressure, and automatically records all parameters throughout the process.

⑦ External Dimensions: Aging Chamber: 600×450×450mm

2. TD610-P type standard sample trays: 10

3. 3Kg/0.1g electronic balance: 1 unit

4. TDTM-Q1 type air compressor: 1 unit

III. Preparatory Work

1. Prepare asphalt samples according to the methods in this specification and conduct a rotating thin film oven test (RTFOT). After completing the aging test, pour the residue into a container for later use.

2. Place the standard film oven test sample tray of known mass on a balance, and add 50g ± 0.5g of asphalt to the tray to make the asphalt film thickness approximately 3.2mm. If the residue has cooled, it can be heated to a flowable state before refilling.

IV. Test Procedure

1. Place the sample tray inside the pressure vessel, select the pressure aging vessel temperature according to relevant requirements, turn on the heater, and preheat the pressure vessel to the selected aging temperature. Once the aging temperature is reached, quickly open the pressure vessel, place the prepared sample tray onto the sample holder inside the pressure vessel, and then close the pressure vessel.

2. When the temperature inside the pressure vessel reaches 2°C below the specified temperature (required to be reached within 2 hours), supply air pressure of 1 MPa ± 0.1 MPa and start timing. Maintain the temperature and air pressure inside the pressure vessel for 20 hours ± 10 minutes.

3. After the specified 20-hour aging time, open the pressure reducing valve to reduce the pressure inside the pressure aging vessel (PAV) to the same level as the external pressure within 5-15 minutes.

4. During the 20-hour aging period, if the temperature recorded by the temperature recording device is higher or lower than the target aging temperature by 1 ± 0.5℃ for a total time exceeding 60 minutes, the aging process is invalid and the test sample is discarded; similarly, if the pressure exceeds the specified range, the test sample is also discarded.

5. Open the pressure vessel, remove the test rack and sample tray, pour the hot residue from the tray into a container, add gas and stir to remove air bubbles, then immediately perform performance testing on the pressure aging (PAV) residue. If the residue is not to be tested immediately, it should be covered and stored at room temperature for later testing.

6. Report: The report after the test includes: sample number, aging temperature, accurate to 0.5℃; record of the highest and lowest aging temperatures, accurate to 0.1℃; total aging time, accurate to 1 min.